Flexible, biodegradable, and high-performance piezoelectric devices are the new frontier explored by researchers at the Istituto Nanoscienze (Cnr Nano). Led by Luana Persano, in collaboration with the University of Pisa, the University of Wisconsin-Madison (USA), and the Scuola Normale Superiore, the team has developed an innovative technology that combines naturally derived nanomaterials with degradable metal layers, opening the way for advanced and sustainable medical solutions. The study has been published in Science Advances.

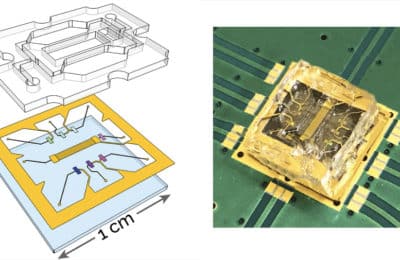

Piezoelectric devices, which can convert pressure or vibrations into electricity and vice versa, have been fabricated using cellulose nanocrystals assembled with molybdenum, a metal, into multilayered structures. The resulting device exhibits record-breaking pressure sensitivity and generates enough power to enable real-time heart rate monitoring. Additionally, it efficiently converts mechanical movement into electrical energy (energy harvesting), making it possible to power small electronic devices—such as wearable or implantable sensors—without relying on batteries, thereby reducing e-waste concerns.

“The biocompatibility of these devices has been validated through tests on lung epithelial and cardiac muscle cells, as well as in vivo experiments, confirming their potential for medical applications,” explains Persano. “Possible applications include organ monitoring, controlled drug release, and regenerative medicine, paving the way for self-powered, highly sensitive, and eco-friendly medical devices,” she adds.

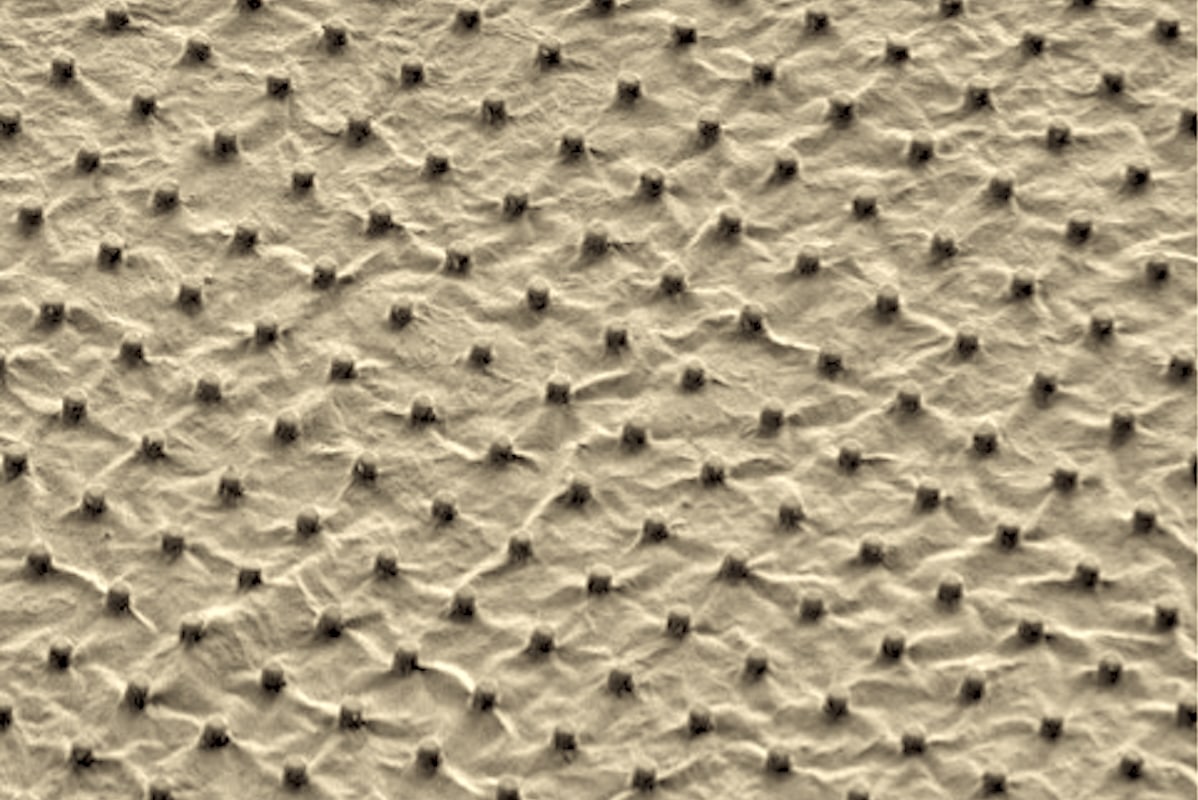

It is well known that biocompatible and biodegradable piezoelectric materials like cellulose nanocrystals could offer a sustainable alternative for transient electronics and biomedical implants. However, unlocking their full potential requires methods to assemble them into large-scale, high-performance structures. The solution developed by the research team addresses this challenge, introducing a scalable multilayer system in which cellulose nanocrystals are arranged to achieve an exceptional piezoelectric response. Persano says: “Our method is scalable, employs submicrometer-scale patterning to enhance material performance, covers areas on the order of square centimeters, and achieves an outstanding piezoelectric response, with a record output power of 0.6 μW/cm² and a pressure sensitivity of 4.2 V/kPa in the soft-touch range (0.76-4.55 kPa).”

“The combination of nano- and microfabrication techniques has enabled us to develop a unique platform that merges sustainability with advanced research, laying the groundwork for a future where electronic devices seamlessly integrate with our bodies and environment,” concludes Persano.

The study, conducted primarily in Pisa at the Nest laboratory—where Cnr Nano laboratories are also based—was carried out within the framework of the European Marie Curie BIOIMD program. It benefited from the collaboration of Alessandra Operamolla’s research group, which synthesized the nanocrystals, and Dario Pisignano’s team at the University of Pisa. While the Cnr Nano team behind this study includes researchers Luana Persano, Sujoy Kumar Ghosh, Francesca Matino, Ilaria Tonazzini, J. Gustavo De La Ossa G. and Andrea Camposeo.

Original article: Fully biodegradable hierarchically designed high-performance nanocellulose piezo-arrays, Sujoy Kumar Ghosh et al. Science Advances .11,eads0778(2025).DOI:10.1126/sciadv.ads0778