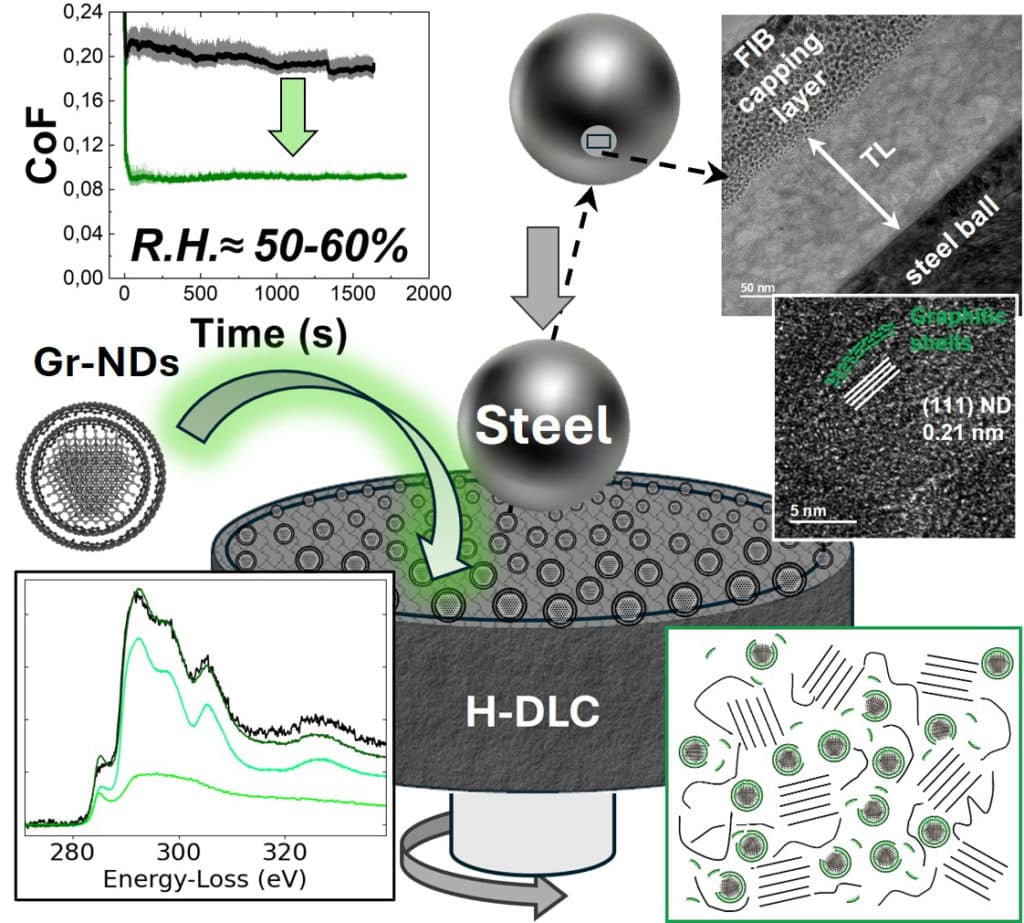

Researchers at Cnr Nano have developed a new process for optimising diamond-like carbon coating that maintains ultra-low friction even in humid environments—a long-standing challenge for these widely used solid lubricant materials. The study, recently published in Small structures, shows that spraying specially designed graphitic nanodiamonds (Gr-NDs) to commercial Diamond-like carbon (DLC) coatings can enhance their performance without the need of sophisticated treatments.

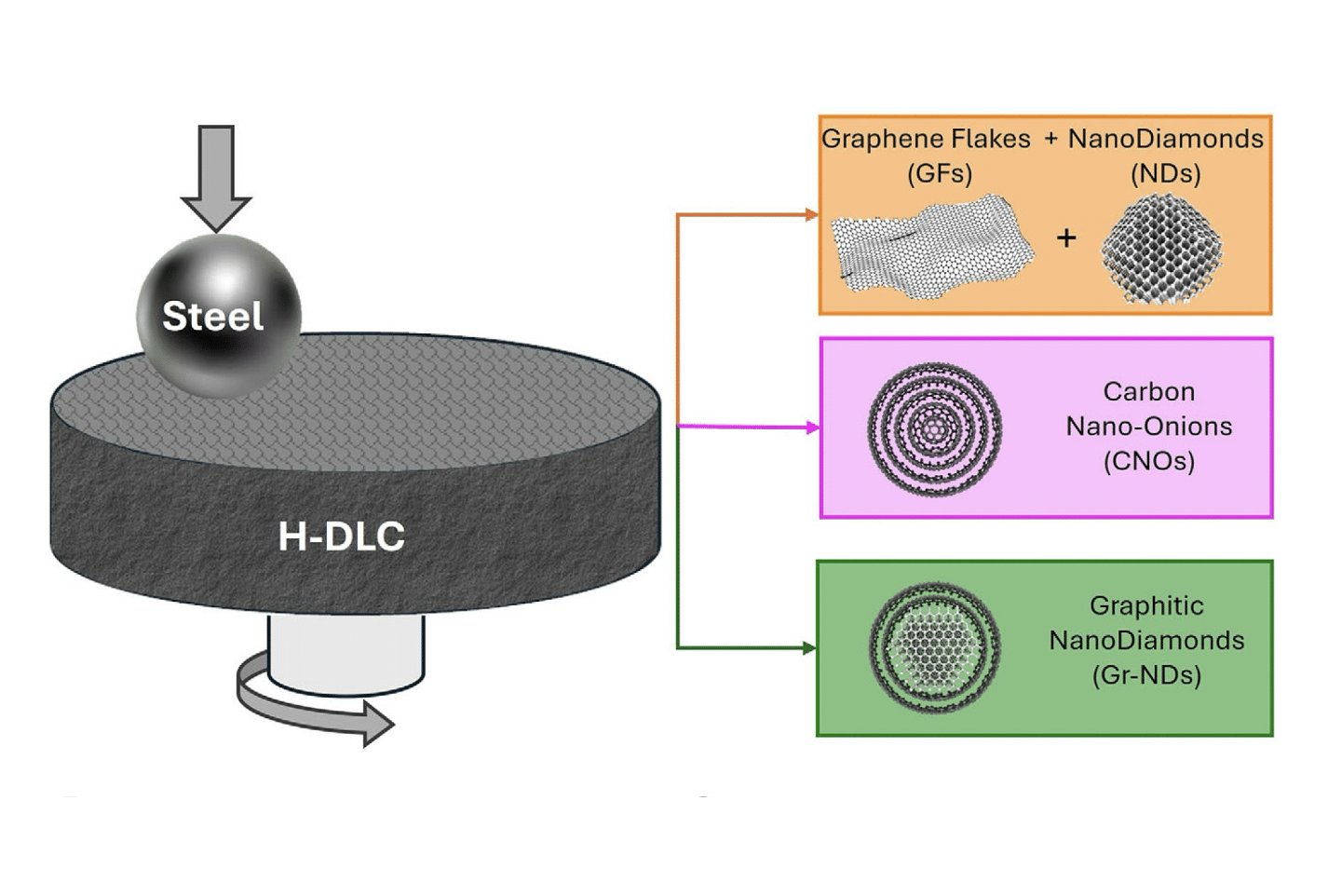

DLC coatings are widely used in various industrial fields, including biomedical applications, due to their hardness, chemical stability, and naturally low friction. However, their effectiveness often drops when exposed to humidity. The team, led by Guido Paolicelli and Andrea Mescola from Cnr Nano, explored the use of graphitic nanodiamonds—carbon-based nanoparticles with a core–shell structure—as functional additives to overcome this problem.

“These graphitic nanodiamonds act as a built-in lubricant,” explains Mescola. “They help form a protective graphitic layer directly at the contact surface during operation, which greatly reduces friction and wear—even in humid conditions where most conventional DLC coatings fail.”

The researchers found that this approach allows the DLC coatings to reach ultra-low friction levels, with a coefficient of friction below 0.1 specially against metal surfaces The analysis is supported by high-resolution transmission electron microscopy (TEM), which confirmed that the nanoparticles retain their characteristic core–shell structure while remaining embedded in the surface layer, stabilizing it and ensuring durable performance. This strategy is unique because it enables DLC coatings to maintain their performance in realistic humid environments, unlike other methods based on nanoparticles or 2D materials that often fail under moisture.

The implications of this work are significant for a range of applications with a potential impact on industries ranging from automotive to biomedical. Enhanced DLC coatings could improve the efficiency and longevity of mechanical components such as engines, bearings, and gears, and support medical devices and electronic components that must operate reliably in humid conditions. By reducing wear, these coatings can lower maintenance costs and contribute to more sustainable technologies.

The research was carried out through a collaborative effort: nanoparticle synthesis and characterization were performed in partnership with prof. Silvia Giordani at Dublin City University, while Gian Carlo Gazzadi and Giovanni Bertoni at Cnr Nano Modena conducted detailed TEM and spectroscopic analyses of the contact regions. Renato Buzio from Cnr Spin Institute contributed to the interpretation of tribological data, providing a comprehensive understanding of the mechanisms behind the ultra-low friction.

Looking ahead, the team plans to test the coatings under higher humidity levels and explore alternative core–shell nanoparticle designs to further enhance performance.

This research was supported by the ECOSISTER project funded under the National Recovery and Resilience Plan (NRRP, NextGenerationEU, Award No. 0001052) and by the Italian Ministry of University and Research (Decree 128-21/06/2022, contract no. IR0000027 ‘Infrastructure for Energy Transition and Circular Economy – iENTRANCE@ENL’).

Reference: Mescola, A., Bertoni, G., Gazzadi, G.C., Bartkowski, M., Camisasca, A., Giordani, S., Buzio, R. and Paolicelli, G. (2025), Humidity-Resistant Ultralow Friction in Diamond-Like Carbon Coatings Enabled by Graphitic Nanodiamonds. Small Struct. 2500236. https://doi.org/10.1002/sstr.202500236